Se comunica a todos los postulantes inscritos en el Proceso de Admisión 2025 de la Escuela de Educación Superior Pedagógica Pública “Generalísimo José de San Martín” que, en atención a lo dispuesto en la Resolución Ministerial N° 130-2025-MINEDU, artículo 5, numeral 5.1.7.8, inciso f, que señala:

“Conforma las secciones para el desarrollo de los cursos, módulos u otras experiencias formativas de cada programa de estudios, con un mínimo de 10 y un máximo de 30 estudiantes.” y en cumplimiento estricto de dicha norma, la cual entra en vigencia a partir del semestre 2025-II se ha dispuesto que el número de vacantes ofertadas para este proceso de admisión será de treinta (30).

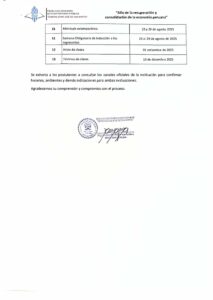

Descargar Comunicado Modificación Admisión